Were you unable to attend Transform 2022? Check out all of the summit sessions in our on-demand library now! Watch here.

John Deere is known for its industrial-grade agricultural, forestry and heavy equipment, as well as its consumer lawn care line.

But many probably don’t realize that it is also incorporating leading-edge capabilities including AI, computer vision, data analytics, digital twins, sensors, robots and co-bots — proving that 185-year-old manufacturing companies can go through digital transformation, too.

In June, we reported on how John Deere is using AI to harvest data. At VentureBeat’s Transform 2022 event last week, its CIO Ganesh Jayaram reiterated this and highlighted the other innovative efforts the company is embracing to propel it forward.

“You can think of that as ‘Industry 4.0,’” John Deere CIO, Ganesh Jayaram, said in a livestream keynote during last week’s Transform 2022.

Manufacturing at the edge

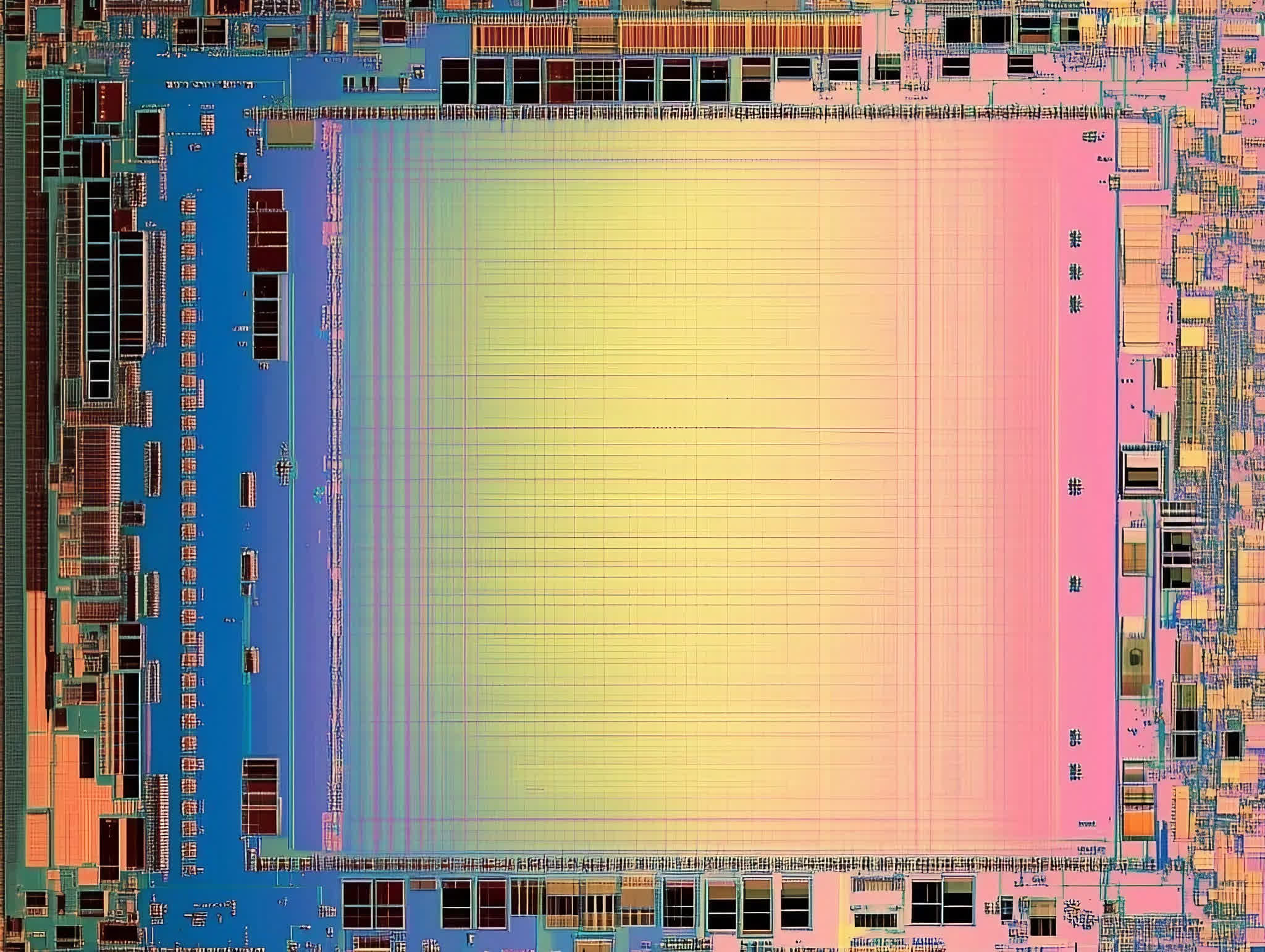

John Deere’s tech strategy is built around two tenets, explained Jayaram: the public cloud and the edge.

“There’s a need for both,” he said — it’s just a matter of defining what types of workloads take place where.

The edge is best for applications with low latency, “where you really don’t have the time to be sending the information back to the cloud.”

For John Deere, that edge is factory and warehouse operations, said Jayaram. The company is scaling knowledge at the edge and investing in private server networks.

“We’re trying to drive compute and analytics, leverage intelligence at the edge, as close to the point of impact as possible,” he said. “We want to translate intelligence at the edge so that those applications with high bandwidth and low latency can perform there.”

The manufacturing tech stack

Along with this, Jayaram described an emergent tech stack. The best way to conceptualize that in the manufacturing world is to combine IT and OT, he said — that is, adding manufacturing components to a core IT stack.

The top layer of this stack combines applications and analytics. Just beneath that is the data platform. Under that are platforms of connectivity and software (enterprise resource planning software, for example). Lastly, hardware and services. And cutting across that layer of stack, explained Jayaram, is cybersecurity.

Ultimately, data is the engine that drives all of this, he said. The company has invested heavily in what it describes as a “John Deere data factory” comprising a data lake.

“That core analytics function has to be driven on really reliable data that cuts across our internal silos [of manufacturing, engineering, supply chain],” said Jayaram. “We’re bringing in these different streams of data, curating the data and making sure that the data is the highest quality, that it is well cataloged.”

Agile operations

To further drive innovation, John Deere has implemented an agile operating model across the business.

For instance, the same principles and concepts that are applied to software development are practiced on the shop floor.

“It’s not uncommon to find these (manufacturing) teams swarming on ideas or challenges,” said Jayaram. “Teams come together, they swarm on an idea and they really try to drive a solution in a matter of days.”

Since rolling out the model, support incidents are down, there has been a two to three-fold increase in customer features and a ten-fold increase in the number of deployments.

“Our teams really love this new way of working with that focus on customer centricity,” said Jayaram.

And even further afield?

Responding to the inevitable question about the metaverse, Jayaram said that John Deere is “very excited” about the implications — “but we are also early days of the journey.”

His team is analyzing the applicability of the metaverse in operations, he said. He also forecasted “several breakthroughs” when it comes to digital twin technologies.

For instance, at a Consumer Electronics Show earlier this year, the company introduced a technology allowing anyone to virtually sit inside a tractor just using their mobile devices. John Deere is also introducing the digital twin concept into engineering and manufacturing processes.

“If you’re able to provide a digital experience that mimics the physical world,” said Jayaram, “it enables customers and employees to be much more engaged with the product.”

Watch the full-length conversation from Transform 2022.

Discussion about this post