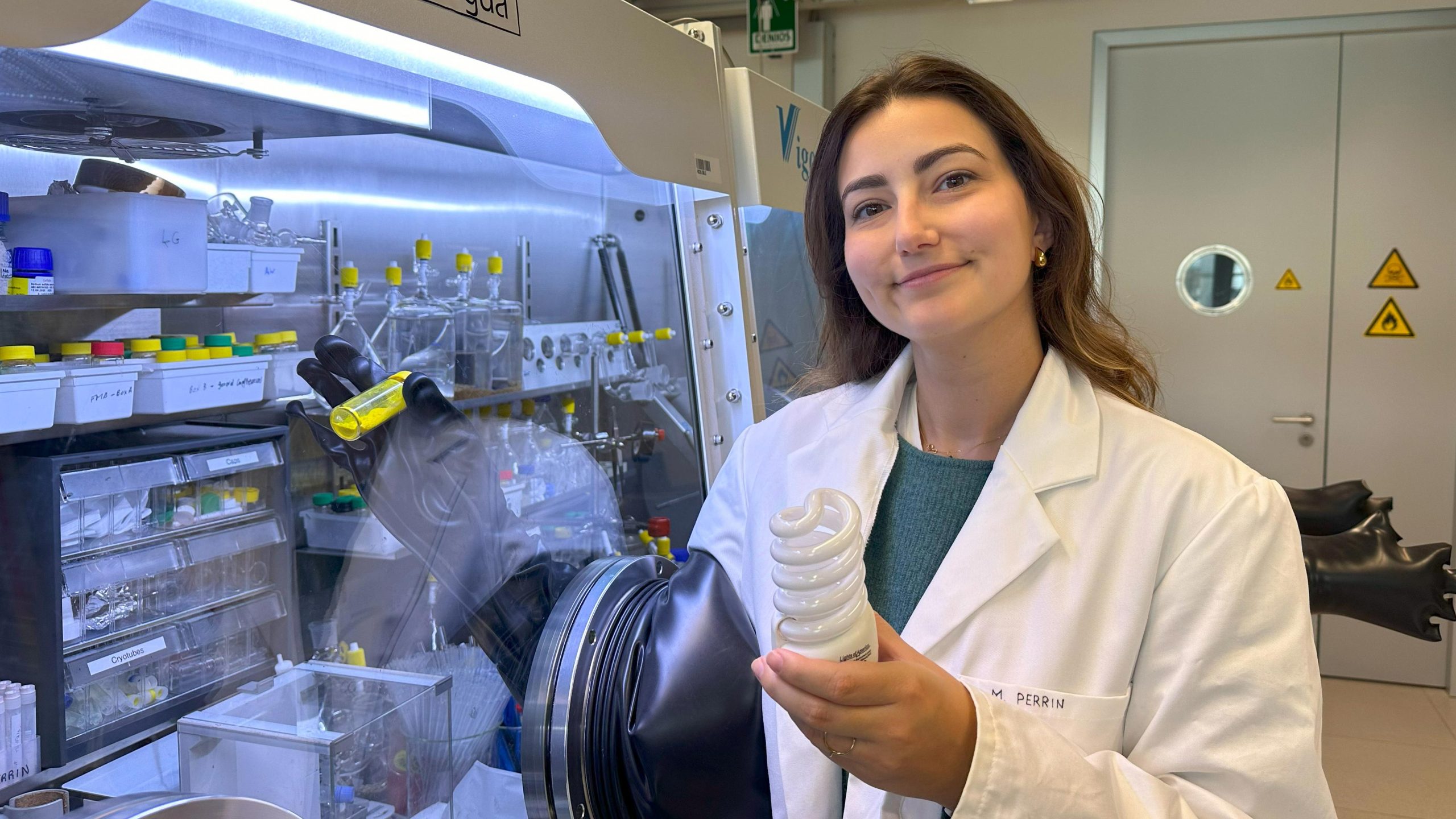

ETH doctoral student Marie Perrin presents the new recycling approach. In her left hand, she is holding the raw material in the form of a fluorescent lamp and, in her right, the yellow reagent that can separate rare earth metals. Credit: Fabio Masero / ETH Zurich

Scientists are developing a process inspired by nature that efficiently recovers europium from old fluorescent lamps. The approach could lead to the long-awaited recycling of rare earth metals.

- A small molecule that naturally serves as a binding site for metals in enzymes also proves useful for separating certain rare earth metals from each other.

- In a proof of concept, the process extracts europium directly from fluorescent powder in used energy-saving lamps in much higher quantities than existing methods.

- The researchers are now working on expanding their approach to other rare earth metals. They are in the process of founding a start-up to put the recycling of these raw materials into practice.

Rare earth metals are not as rare as their name suggests. However, they are indispensable for the modern economy. After all, these 17 metals are essential raw materials for digitalization and the energy transition. They are found in smartphones, computers, screens, and batteries – without them, no electric motor would run and no wind turbine would turn. Because Europe is almost entirely dependent on imports from China, these raw materials are considered to be critical.

However, rare earth metals are also critical because of their extraction. They always occur in compound form in natural ores – but as these elements are chemically very similar, they are difficult to separate. Traditional separation processes are therefore very chemical- and energy-intensive and require several extraction steps. This makes the extraction and purification of these metals expensive, resource- and time-consuming and extremely harmful to the environment.

Innovative Recycling Techniques

“Rare earth metals are hardly ever recycled in Europe,” says Victor Mougel, Professor at the Laboratory of Inorganic Chemistry at ETH Zurich. A team of researchers led by Mougel wants to change this. “There is an urgent need for sustainable and uncomplicated methods for separating and recovering these strategic raw materials from various sources,” says the chemist.

In a study recently published in the journal

Rapid recycling of europium from fluorescent lamps. Credit: Marie Perrin / ETH Zurich

Practical Applications and Environmental Impact

“The principle is so efficient and robust that we can apply it directly to used fluorescent lamps without the usual pre-treatment steps,” says Mougel.

Electronic waste is an important but as yet underutilized source of rare earth metals. “If this source were tapped into, the lamp waste that Switzerland currently sends abroad to be disposed of in a landfill could be recycled here in Switzerland instead,” says Mougels. In this way, lamp waste could serve as an urban mine for europium and make Switzerland less dependent on imports.

“Our recycling approach is significantly more environmentally friendly than all conventional methods of extracting rare earth metals from mineral ores.”

— Victor Mougel

In the past, europium was mainly used as phosphor in fluorescent lamps and flat screens, which led to high market prices. As fluorescent lamps are now gradually being phased out, demand has fallen, so that the previous recycling methods for europium are no longer economically viable. More efficient separation strategies are nevertheless desirable and could help to utilize the vast quantities of cheap fluorescent lamp waste whose rare earth metal content is around 17 times higher than in natural ores.

Strategic Recycling Efforts

This makes it all the more urgent to recover rare metals at the end of a product’s life and keep them in circulation – but the recovery rate of rare earth elements in the EU is still below one percent.

In principle, any separation process for rare earth metals can be used both for extraction from ore and for recovery from waste. With their method, however, the researchers are deliberately focussing on recycling the raw materials, as this makes much more ecological and economic sense. “Our recycling approach is significantly more environmentally friendly than all conventional methods for extracting rare earth metals from mineral ores,” says Mougel.

New Ventures and Commercialization

The researchers have patented their technology and are in the process of founding a start-up called REEcover to commercialize it in the future. They are currently working on adapting the separation process for other rare earth metals such as neodymium and dysprosium, which are found in magnets. If this is successful, Marie Perrin wants to build up the start-up after her doctorate and establish the recycling of rare earth metals in practice.

Reference: “Recovery of europium from E-waste using redox active tetrathiotungstate ligands” by Marie A. Perrin, Paul Dutheil, Michael Wörle and Victor Mougel, 3 June 2024, Nature Communications.

DOI: 10.1038/s41467-024-48733-z

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer_public/d1/82/d18228f6-d319-4525-bb18-78b829f0791f/mammalevolution_web.jpg)

Discussion about this post