Researchers from the University Alliance Ruhr, Germany, have discovered a catalyst enabling the conversion of ammonia into hydrogen and nitrite, potentially merging hydrogen production and fertilizer creation. By using gas diffusion electrodes and a suitable multi-metal catalyst, they achieved a significant electron conversion rate and demonstrated the feasibility of combining the reverse Haber-Bosch reaction with water electrolysis, although industrial application is still distant.

German researchers have created a catalyst that converts ammonia into hydrogen and nitrite, potentially combining hydrogen production and fertilizer creation in one process.

A research team from the University Alliance Ruhr in Germany has discovered a catalyst capable of converting ammonia into both hydrogen, an energy carrier, and nitrite, a precursor for fertilizer. Traditionally, the production of hydrogen and fertilizer has involved separate chemical processes.

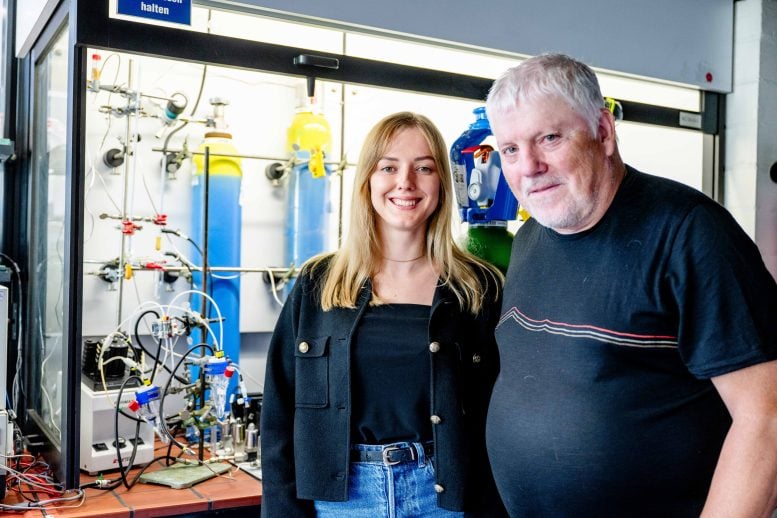

With the new approach, the team from Ruhr University Bochum and the University of Duisburg-Essen is demonstrating that the two can be combined on a laboratory scale. The Bochum-based group led by Ieva Cechanaviciute and Professor Wolfgang Schuhmann reports on the results together with Bhawana Kumari and Professor Corina Andronescu from the University of Duisburg-Essen in the journal Angewandte Chemie International Edition.

Hydrogen can be produced by splitting water (H2O) into hydrogen (H2) and oxygen (O2) using electrical energy. To make this process sustainable, the energy should come from renewable sources. “This can only be done in a country where there is plenty of space for wind power and lots of sun for photovoltaics, for example in Namibia,” explains Wolfgang Schuhmann. In order to build an economy based on hydrogen in Germany, it must therefore be imported from distant countries. The crux of the matter is that a lot of energy is needed to liquefy hydrogen for transport, as it only becomes liquid at extremely low temperatures of minus 253 degrees

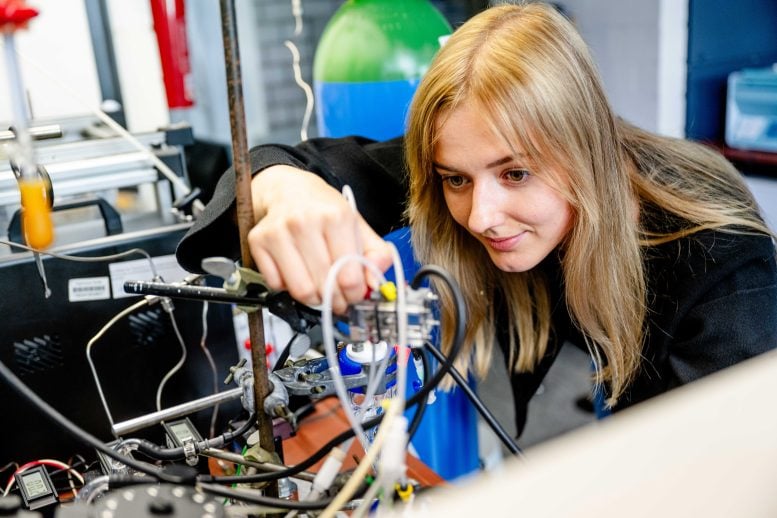

Ieva Cechanaviciute. Credit: RUB, Marquard

Ammonia is easier to transport than hydrogen

Alternative concepts therefore envisage converting hydrogen into ammonia at the production site, as this becomes liquid at minus 33 degrees Celsius. It also has a higher energy density. “A tanker full of liquid ammonia would transport around 2.5 times more energy than a tanker full of liquid hydrogen,” explains Schuhmann. Finally, ammonia would have to be converted back into hydrogen at the point of use. This is usually done using the reverse Haber-Bosch reaction, in which ammonia (NH3) is converted into nitrogen (N2) and hydrogen (H2). Of the two products, however, only the hydrogen can be utilized profitably.

Double the hydrogen yield

“We therefore had the idea of combining the reverse Haber-Bosch reaction with a second electrolysis of water to produce a product that can easily be used for the production of fertilizer, such as nitrite or nitrate, instead of nitrogen,” explains Ieva Cechanaviciute. In this reaction, ammonia (NH3) and water (H2O) are consumed to produce nitrite (NO2–) and hydrogen (H2). In contrast to the reverse Haber-Bosch reaction, the hydrogen output is doubled and instead of nonusable nitrogen, mainly nitrite is produced, which can be further processed into fertilizer.

For the reaction, the team used gas diffusion electrodes into which ammonia can be fed as a gas. “This had never been done before,” explains Wolfgang Schuhmann. “Ammonia was always used in dissolved form.”

RUB, MarquardPart of the Bochum research team: Ieva Cechanaviciute and Wolfgang Schuhmann. Credit: RUB, Marquard

Overcoming the thermodynamic canyon

One challenge for the researchers was to find a suitable catalyst with which their idea could be realized. This is because the starting material NH3 tends to convert into nitrogen due to the very strong nitrogen-nitrogen triple bond and not into nitrite. “We first had to bridge this thermodynamic Grand Canyon,” explains Cechanaviciute. In earlier work, the team had already experimented with multi-metal catalysts, which proved to be suitable for this purpose. They were able to convert 87 percent of the transferred electrons into nitrite. The team also managed to avoid oxygen as an undesirable by-product of water electrolysis.

“Our work shows that our Gedankenexperiment can work in principle,” summarizes Wolfgang Schuhmann. “But we are still a long way from technical implementation on an industrial scale.”

Reference: “Gas Diffusion Electrodes for Electrocatalytic Oxidation of Gaseous Ammonia: Stepping Over the Nitrogen Energy Canyon” by Ieva A. Cechanaviciute, Bhawana Kumari, Lars M. Alfes, Corina Andronescu and Wolfgang Schuhmann, 23 June 2024, Angewandte Chemie International Edition.

DOI: 10.1002/anie.202404348

The study was funded by the German Research Foundation and the European Research Council.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer_public/34/31/3431771d-41e2-4f97-aed2-c5f1df5295da/gettyimages-1441066266_web.jpg)

Discussion about this post