The global supply chain covers a complex network of manufacturers, suppliers, distributors, wholesalers, retailers, and customers. So, how does a business ensure every product reaches the right location at a definite time range? It’s through supply chain management – a strategic process of planning and overseeing logistics, facilitated by an effective logistic management system, to ensure a safe transition from suppliers to customers.

As businesses scale rapidly, the manual supply chain process has proven to be ineffective in handling the complexities of procurement to distribution. Developing supply chain software not only helps to simplify the process but also reduces costs and errors for leveling up productivity to meet global demand. IBM stated that organizations that follow advanced SCM capabilities are found to be 23% more profitable.

After analyzing the critical role of the supply chain in modern business, which provides better operation management and manages risks, the question arises: What will be the supply chain software development cost? The cost to develop a supply chain software can range from $50,000 to $5,00,000 depending on key factors, basic features like inventory tracking, order management, and integration affect the cost of building supply chain software that we’ll be discussing later in this guide.

According to the Statistics report, supply chain management software will generate revenue of $24.58 billion at a CAGR of 4.14% by 2029. Due to profitable projections, businesses are aiming to invest in developing supply chain software.

By the end of this guide, you’ll gain valuable insights into the key factors influencing the costs of Supply Chain Software Development Services, helping you make informed decisions that optimize both your budget and business outcomes.

What is Supply Chain Software?

Supply chain software is a technology platform developed to automate the operation process of demand forecasting, inventory management, and transportation logistics. Supply chain management covers the entire production cycle from storage of raw materials, work-in-progress inventory, and finished products for final delivery to customers. Digitally, this software provides a centralized view for addressing bottlenecks and real-time tracking for better coordination between suppliers or manufacturers and customers.

Benefits of Supply Chain Software

Here are the following advantages that businesses gain due to supply chain software:

1. Minimize Cost

It reduces inventory holding costs with better control management and fewer overhead expenses through online optimization of logistics.

2. Operational Efficiency

Unlike manual processes, supply chain software provides better real-time data insights, optimized workflows, and streamlined processes.

3. Financial Visibility

This tool captures real-time data and financial insights for proactive identification from procurement to delivery.

4. Improved Customer Services

It shortens the operation cycle and enables fast order fulfillment, better delivery times, and better customer satisfaction.

5. Risk Mitigation

Tracking supply chain bottlenecks and an inbuilt alert mechanism for overstock helps identify and mitigate potential disruptions.

Struggling with Supply Chain Challenges?

Simplify your operations with a custom supply chain software solution.

How Much Does Supply Chain Management Software Cost? [Quick Answer]

Handling the entire supply chain process can be a challenging task for a business, so opting for software can simply process and provide efficient results. But, what is the overall cost to build supply chain software? It depends on the complexities of software to determine the cost of development, a few businesses might require limited features, while others need a complete solution package.

Let’s understand the fundamentals to find out the cost to develop a supply chain software with reference to this table below:

| Components | Complexities | Estimated Cost | Timelines |

|---|---|---|---|

| Basic Research | Understanding the complexities of logistics and creating a blueprint for procurement, storage, and distribution | $1000-$5000 | 4 to 7 Weeks |

| UI/UX Design | Creating a user-friendly interface based on business requirements, locating tabs, tags, and pages | $3,000 – $15,000 | 8 to 12 Weeks |

| Software Features | Inventory tracking, order management, AI analytics, IoT integration | $10,000 – $50,000 | 3 to 5 Weeks |

| Technology Stack | Programming language, frameworks & libraries, database, cloud computing, machine learning, and analytics tools | $5,000 – $20,000 | 8 to 24 Weeks |

| QA & Testing | Function testing and performance, security, usability, and compatibility testing, along with test case and reporting | $5,000 – $20,000 | 10 to 16 Weeks |

| Compliance & Security | Implementing security checks and integrating regulatory compliance for cybersecurity measures | $5,000 – $25,000 | 4 to 12 Weeks |

| APIs Integration | Integrating ERP systems, WMS warehouse management systems, transportation management systems (TMS), e-commerce platforms and third-party logistics providers | $5000 – $30,000 | 2 to 8 Weeks |

| Deployment Costs | Initial setup, licensing, and hosting of cloud and servers | $3,000 – $15,000 | 2 to 4 weeks |

| Maintenance & Post-Launch Support | Updates, maintenance, and troubleshooting after deployment | $5000-$30,000 | Weekly, Monthly, or Yearly |

If we bifurcate the estimated Supply Chain Software development cost on multiple ranges, it would come around these figures:

- For simple or small-scale supply chain management software for small business with basic features, it will fall under the range of $30,000 – $50,000.

- If the business wants to level up with customized and modern features, then the supply chain development cost would be $50,000 – $1,50,000.

- For big or enterprise-level software with all advanced features, it might range beyond $1,50,000.

Overall, the cost to build supply chain software will significantly depend on the scope of the business, the current supply chain process, timelines, and other specific business requirements. Let’s discuss this further in the blog ahead.

10 Factors Affecting the Cost to Build Supply Chain Software

Multiple factors affect the cost to develop supply chain software. Some of the relevant key factors are:

1. Complexities and Scope

Assessing the scope of supply chain management and the complexities involved is the foremost factor that impacts the cost of software. If advanced functionalities are required, more resources and expertise are required for customized development, along with extensive testing for each feature.

2. Software Integration

Additional software setups like Enterprise Resource Planning ERP or Customer Relationship Management tools will increase the overall cost of developing supply chain software. So, depending on the complexities of integration and project timelines, the cost will vary. Businesses can either integrate software or buy a specific one for order processing, inventory management, warehouse management, or procurement software.

3. Training & Implementation

It is an integral factor that is overlooked when estimating the cost of development. Large-scale businesses that operate in multiple locations would require more extensive training and support, which would lead to higher costs. Although online learning and guiding manuals are speeding the adaptability, they still create demand for a robust infrastructure to support training.

4. Functionality

If a business requires adding more features and functionalities to supply chain software, including inventory management, delivery optimization, AI-based tracking, demand forecasting, or warehouse management, it will cost more. Indeed, certain automation features will reduce human errors, speed up order fulfillment, and improve accuracy, but they will create additional charges above the base cost.

5. Scalability

Depending on the small or large scale, there will be less and a larger volume of data to integrate with supply chain software. This creates additional costs for developing infrastructure to manage scalability and performance. New-age technologies like AI, machine learning, and blockchain have proven to be more effective in eliminating risks and supply chain management vulnerabilities.

6. Approach

The cost of developing in-house will vary, as it requires more resources, time, and the hiring of skilled engineers. If the business outsources to a Supply Chain software development company, it will save time and amount to a more cost-effective solution. Otherwise, there are low-code and no-code platforms available for basic software that save more cost but have limitations for scalability.

7. User Interface

Multiple users are involved within the supply chain cycle, each with their own needs and expectations. Selecting the right user interface would be feasible to increase coordination and collaboration. However, adding features such as data visualization, AI reporting, workflow optimization, mobile optimization, and a feedback mechanism will create cost requirements.

8. Technology Opted

Nowadays, due to technological advancement, businesses can use cloud computing, which is a cost-effective and scalable solution. On the other hand, emerging technologies like artificial learning, machine learning, or blockchain will increase development costs but provide long-term benefits.

9. Project Management & Team

Another factor that directly impacts the cost to develop a supply chain management software is the project’s scope and timelines that minimize costs. Also, a well-skilled and experienced team of engineers as a development team would result in saving resource wastage and training costs, which would reduce development costs.

10. Maintenance & Support

After the launch of supply chain software, the business has to cover ongoing expenses of updates, add-on features, and bug fixes for further development that supports long-term functionalities. If it is outsourced software, there will be renewal charges as well.

Tired of Supply Chain Delays?

Optimize every step with custom-made supply chain software.

Must-Have Features to Build Supply Chain Software

While developing supply chain software, there are a few must-have features that make it an ideal choice for optimizing business operations and efficiency. So, it is essential to assess the requirements before opting for supply chain software development services. Some of these features that ensure core functionality are:

1. Inventory Management

This feature uses real-time tracking to provide updated insights into inventory levels across warehouses and distribution centers. Using AI-based technology, it manages inventory procurement, storage, and distribution for customers. Further, the built-in demand forecasting feature will help support future demand and optimize stock levels.

2. Efficient Order Processing

Whether it’s a small-scale or large-scale business, a larger number of users can significantly increase demand. For a fast-paced supply chain cycle, order management helps control order processing, fulfillment, and tracking. Also, shipping integration can help with real-time tracking and cost optimization.

3. Procurement

It focuses on shaping supplier management by creating contracts, performance evaluations, and payment processing. Purchase order management helps create and track purchase orders for suppliers. It also includes additional features such as requests for quotes and requests for proposals to make it convenient for parties.

4. Advanced Warehouse Operations

This operates to streamline the process of receiving and storing goods, optimizing order picking and packing for more efficient warehouse management. It helps manage inbound and outbound shipments for businesses by setting up a standard process of goods storage and timely deliveries.

5. Transportation Management

Transportation has been an integral part of the supply chain cycle, so TMS supports route optimization while minimizing costs and delivery times. It optimizes the key data of prices, delivery times, and service levels that help manufacturers select the right carriers for deliveries. Also, freight tracking helps to track shipments in real-time.

6. Supply Chain Analytics

It creates a dashboard and reports highlighting key performance indicators for tracking supply chain performance. The additional feature of data analysis supports the identification of trends and bottlenecks for data-driven decision-making. Additionally, advanced features help forecast demand, potential disruptions, and supply chain operations.

Tips to Reduce the Costs of Developing Supply Chain Software

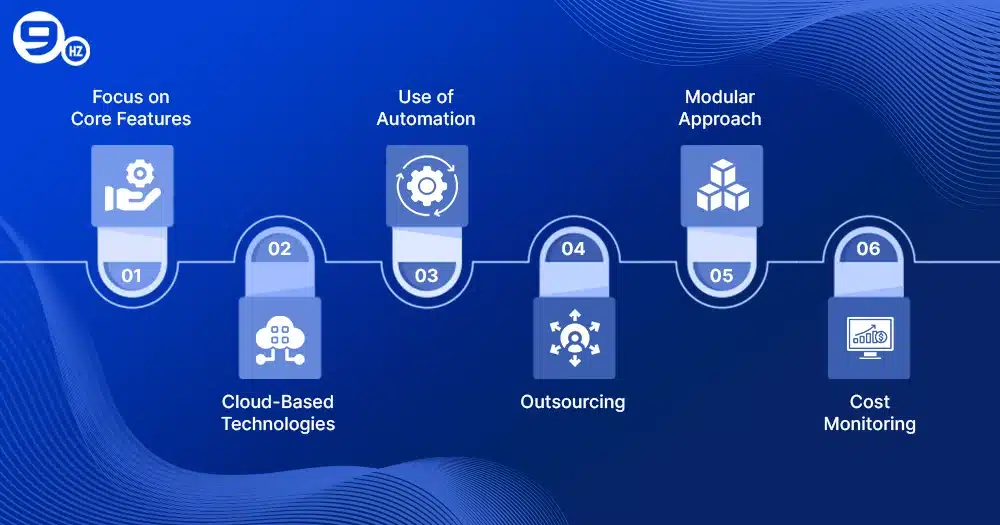

Supply chain development costs are significant for any small or big-scale business. The developer’s team focuses on cost-effective ideas that save their budget allocation by getting the best results:

1. Focus on Core Features

Businesses can adopt agile development mechanisms to focus on core functionality and develop minimum viable supply chain software. This helps reduce costs by avoiding features that do not support scaling supply chain management and sticking to specific ones, such as inventory management and logistics.

2. Cloud-Based Technologies

Using cloud-based platforms like AWS and Google Cloud for better infrastructure helps create suitable infrastructure with more scope for scalability to adopt new trends. For further cost reduction, they can also rely on open-source technologies and explore more low-code platforms to avoid licensing costs and develop software with minimal cost.

3. Use of Automation

Traditionally, manual testing requires more team support and resource allocation, but automation tools eliminate manual testing costs to deliver better quality assurance and fix bugs and issues. They also reduce timelines and accelerate development cycles by eliminating redundant tasks.

4. Outsourcing

Developing supply chain software is a complex process that requires streamlined steps, the right technology, testing, and feature upgradation. So, if companies are struggling with a lack of expert developers, it will be viable to outsource tasks across regions where the development costs are comparatively lower with expert services.

5. Modular Approach

Use modular components that allow for easy maintenance, updates, and future scalability. It focuses on designing independent and self-contained components targeting specific functions like inventory control or warehouse management. Developers can either use it separately or integrate it into the large system for more flexibility and scalability.

6. Cost Monitoring

Adopting the measure of keeping a tracking record of financials and development costs will help identify potential cost overestimation and adjustments. For better analysis, companies can create a blueprint for financial management with an estimated budget so as not to suffer losses and additional expenses later on.

5 Best Supply Chain Management Software

Businesses are actively seeking out supply chain management software that transforms operations into automation processes for better optimization. After exploring supply chain development costs, here are the top 5 supply chain software programs that businesses use to run their operations:

| Software | Key Features | Deployment | Primary Use Case | Industries |

|---|---|---|---|---|

| SAP SCM (Supply Chain Management) | Integrated Planning, Real-time Visibility, Collaboration, Analytics and Reporting, Industry-Specific Solutions | Cloud, On-Premise | End-to-end supply chain management | Manufacturing, Retail, Automotive |

| Oracle Supply Chain Management | Product Planning, Inventory Optimization, Order Management, Warehouse Management, Procurement, Predictive Analytics | Cloud | Unified supply chain operations | Healthcare, Consumer Goods, Retail |

| Ramco Supply Chain Management Suite | Sales & Distribution, Inventory Management, Supplier Relationship Management, Warehouse Management, Project Management | Cloud, On-Premise | Enterprise resource management | Construction, Defense, Manufacturing |

| Blue Yonder SCM | AI-Powered Demand Forecasting, Inventory Optimization, Production Planning, Transportation Management, Identify risks and disruptions | Cloud | Demand forecasting and inventory optimization | Retail, Logistics, E-commerce |

| Manhattan Associates | Inventory Optimization, Cloud-Native Solutions, Transportation Management System (TMS), Warehouse Management System (WMS), Demand Forecasting | Cloud, On-Premise | Warehouse and transportation optimization | Retail, Logistics, Distribution |

Types of Supply Chain Software

Here are the different software developed to target the unique segments of supply chain management:

1. Inventory Management System (IMS)

This supply chain software helps to track and manage inventory levels at different locations. It automates order processing to prevent excess inventory conditions and provides real-time visibility to check inventory levels.

2. Warehouse Management Systems (WMS)

This software manages daily warehouse operation activity, including receiving, picking, packing, and shipping of products. It supports warehouse space management, improves labor utilization, and tracks inventory within the warehouse.

3. Logistic Management Systems (TMS)

Logistic management system are designed to optimize deliveries and track shipments in real-time for better safety. Businesses can use the system to establish better coordination among carrier dealers and regulate freight costs. Using Logistics Software Development Services can customize these systems to better fit your business needs and make your supply chain more efficient.

4. Order Management Systems (OMS)

To prevent order mismatch and stock wastage, Custom Order Management Software (OMS) was developed to automate the order fulfillment process, from order creation to delivery. Using an online mechanism, it manages order returns and exchanges and easily integrates with other e-commerce platforms.

5. Supply Chain Planning (SCP) Software

This system supports forecasting demand and creating production planning methods. Using AI-driven tools and sensors, it tracks inventory levels and predicts potential disruptions and risks.

6. Blockchain-based Supply Chain software

Due to the rapidly growing concern of fraud and data breaches, blockchain-based software empowers transparency and traceability for the supply chain to improve data security and reduce system bottlenecks.

Simplify Your Supply Chain Today!

smoothens processes and boost efficiency with custom software solutions.

How Can The NineHertz Help You in Supply Chain Software Development?

The NineHertz is a renowned IT company that provides best custom software development services with over 14 years of experience delivering innovative and customized solutions for the supply chain industry. Our expertise in supply chain software has helped businesses streamline their logistics operations, automate delivery processes, and gain comprehensive end-to-end visibility into their supply chains. With a proven track record of successful projects, we have consistently developed software that drives efficiency, enhances transparency, and optimizes the entire supply chain lifecycle.

- The NineHertz team assists you with app designing with frameworks, and architecture for the best experience with backed service of QA testing & support.

- It guides development using blockchain and AI and easy API integration of supporting tools like ERP, CRM, and WMS.

- Experts help with tools for tracking suppliers’ inventory by inserting details of serial numbers, tags, barcodes, SKUs, and other IDs.

- NineHertz provides collaborative features such as a self-serve internet portal, role-based authorization, inventory reporting, and status reporting.

Conclusion

Supply chain management is a strategic process of operation that completes the product life cycle to its final delivery. However, developing supply chain software has its complexities, and finding the right solution that integrates all services in one place becomes difficult. Also, the factors will vary depending on scope, scalability, and budget allocation for supply chain management. Trusting the right team of engineers and experts will help to explore top features, tailored solutions, and technology to be used.

If you are looking for the best Supply Chain software development company, NineHertz is an ideal platform for enjoying comprehensive services in one place. From software design to testing, it covers all aspects of supply chain management services.

Frequently Asked Questions FAQs

1. How Does Supply Chain Software Work?

Supply chain software integrates the supply chain management process to support and streamline procurement and delivery of goods. It automates processes and uses advanced analytics to provide more efficiency, visibility, and collaboration for the supply chain network.

2. How Much Does Supply Chain Management Software Cost?

The cost of supply chain management (SCM) software varies depending on the size of your business and the complexity of the features you need. Here’s a general cost breakdown:

- For basic SCM software with essential features, the cost typically ranges from $30,000 to $50,000

- If you’re looking for more advanced features like demand forecasting and real-time tracking, costs can range from $50,000 to $150,000.

- For large organizations requiring sophisticated, custom-built solutions, the cost can exceed $150,000, sometimes reaching several hundred thousand dollars.

3. How to Create Supply Chain Software?

Here are the following steps that help in creating supply chain software:

- Step 1: Define supply chain objectives and requirements

- Step 2: Selecting the right technology stack for development

- Step 3: Use the right software architecture to display features

- Step 4: Integrating core features from inventory management to analytics

- Step 5: Decide on the integration of ERP software, third-party logistics, and AI tools

- Step 6: Add security and compliance expectations

- Step 7: Testing software

- Step 8: Deploying supply chain software

4. How Much Does an AI-Powered Supply Chain Software Cost?

If you want to integrate AI into your existing supply chain management software, the cost can range from $10,000 to $100,000 depending on the features you need, such as demand forecasting or real-time analytics. However, if you’re looking to develop a fully AI-powered supply chain management software from scratch, the cost can start at $50,000 and go up to $500,000 or more, depending on the complexity, customization, and deployment type.

5. How to Reduce the Cost to Build a Supply Chain Software?

Following the right approach will support reducing overall cost estimation, such as – developing a minimal viable product, pre-built solutions, and APIs, adopting agile development, and using cloud-based infrastructure. Also, partnering with the development team to outsource will make it more cost-effective.

Discussion about this post